To build, or not to build…With shipping containers that is. It’s the great debate that leaves architects, builders and home owners divided.

We’ve heard the hype about cargotecture and seen shipping container homes pop up all over the world, but is the shipping container really the earth-saving, cost-saving, time-saving, be-all and end-all building material we’ve been led to believe it is?

The key to building successfully with shipping containers is knowing what you’re getting into and understanding both a shipping container’s benefits and limitations. Shipping containers were, after all, built for transport at sea, not for living in.

Let’s take a look at some of the common beliefs and myths about building with shipping containers and have some experts weigh in.

Eco-Friendliness and Sustainability

Myth: Building with shipping containers is the “green” choice because most containers sit in ports, unused and virtually abandoned, accumulating in the hundreds of thousands around the world. Recycling them and converting them into houses is more sustainable and environmentally friendly than building with traditional materials such as wood.

Truth: While many people do choose to build with used shipping containers, a lot of new containers are being used instead. New containers aren’t dented or damaged so are considered safer. Some container home builders say they only uses brand new containers for one important reason- safety.

Debunking the green myth further, Archdaily writes that building a multi-container home can produce a large amount of hazardous waste before it can be used as a residence. Before these homes can be habitable, the entire container should be sandblasted bare and the flooring should be replaced to remove any harmful chemicals that might cause health complications. The openings also need to be cut with a torch or fireman’s saw. There are carbon emissions associated with transport and assembly. Fossil fuels required to move the container into place with heavy machinery contribute significantly to its ecological footprint.

If blanket or panel insulation is going to be used, stud walls will need to be installed which inevitably uses wood (not so eco-friendly). Traditional blanket insulation is also not considered green, but more natural materials such as wool are available.

Last but not least the coatings used to make the containers durable for ocean transport contain a number of harmful chemicals. Wooden floors are also infused with hazardous chemical pesticides to keep pests away.

Our take: If you’re building with a shipping container to be green, speak with a reputable shipping container supplier about sourcing a structurally sound used container rather than buying a new one. Used containers are available in varying conditions, and many have only been used once. Research insulation methods extensively keeping your climate in mind, and use natural materials where possible.

Suitable Building Material

Myth: Shipping containers are prefabricated, ready-to-go with supports and walls, so most of the work is already done. You just need to cut some doors and windows, move them into place, and away you go.

Truth: Depending on what you’re building and how many containers you’ll use, a lot of modification work can be required to turn shipping containers into a habitable dwelling. When walls are removed in multi-container buildings, extensive steel reinforcement is required and this can be very expensive.

According to Mark Hogan, principal architect of New York firm Openscope Studios, shipping containers are unsuitable for large-scale housing projects, not least because of the difficulty in fitting them with heating and cooling systems.

Without a thoughtful and comprehensive temperature control strategy, your shipping container home could be absolutely freezing or a smoking hot box. The right insulation can make a world of difference, but consideration should be given to whether heating or cooling units will be required. These are neither cheap nor environmentally friendly to run.

Another downside is that dimensionally, an individual container can create an awkward living/working space. Taking into account added insulation, you have a long narrow box with less than eight foot ceiling. To make an adequate sized space, multiple boxes need to be combined. As mentioned above, this requires modification and reinforcements.

Elaine Petitgout from Boxman Studios in North Carolina says the advantage of building with shipping containers is the way a container’s shape allows for creativity and flexibility in design. It’s important to remember, however, that while they provide a framework, a lot of work is still needed – think foundation, lighting, plumbing, insulation, new flooring, windows, doors etc.

Petitgout says shipping containers are ideal for industrial office spaces, hospitality suites, trade show booths, and pop-up retail stores, but not so much for residential dwellings.

Building with shipping containers can be like reinventing the wheel, working around a pre-existing structure rather than working with traditional building methods that have been tried, tested and improved over thousands of years. The key is solid planning and research to ensure the build rolls out smoothly.

Our take: Shipping containers provide an excellent starting point for a home, retail outlet or workspace, but they should be considered just that – a starting point. Much more can be involved in the building process than you first imagined.

Ease and Speed of Construction

Common Belief: Building with shipping containers is much faster than traditional construction and is so easy almost anyone can do it.

Truth: The common perception here is close to the mark. The benefit of small shipping container homes is that they can be built extremely quickly and precisely in a factory, then delivered to your land.

A small home can take just three weeks to fabricate in a factory. A lot of modifications can be completed off-site making on-site assembly a quick process, sometimes done within a day.

It is also true that building with shipping containers is more achievable by an avid DIY-er than traditional building. Many people do hire design firms however, or employ contractors who have previous experience building with containers.

One very important thing to keep in mind is building permits. Since using shipping containers to build a home is a relatively new idea, it might be hard to obtain the necessary building permits in your area. This process will likely take longer than the actual build, so start early.

Our take: Depending on your experience, it is possible to build a container home primarily on your own, and quickly. Even for the inexperienced, contractors can be hired to assist in completing your build in a speedy manner. Just make sure you get started on obtaining the right permits and approvals early to avoid delays.

Cost Effectiveness

Common Belief: Building with shipping containers is much cheaper than traditional building methods.

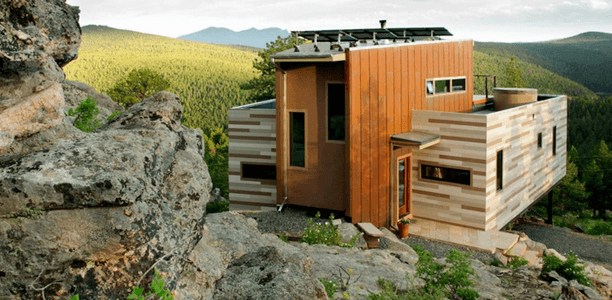

Truth: Building with shipping containers can save money, but it depends what you’re building and where. One man built this self-sustaining off-grid “Taj Malodge” for around $35,000, and this home was built for under $27,000, but just one look at these homes exposes that compromises have been made. They certainly don’t look or function like a standard family home.

So how much would it cost to build something comparable to what you or I are probably used to? That is, a home that’s hooked up to council utilities with 3+ bedrooms and enough room to swing a cat.

Brad Lyons of Container Homes Designer Domain says that “we can sit these $180,000 container homes beside a multi-million dollar home and you wouldn’t know the difference”. This implies that there are still savings to be made on the moderate to luxury-end of housing, but you’ve got to be willing to fork out more than $30,000.

Our take: Building with shipping containers can certainly save money, but be realistic about what you intend to save and what you’re willing to compromise for those savings.

Conclusion

Building with shipping containers is still a relatively new approach to architecture and construction, but the trend is going strong. Cargotecture has created new opportunities for innovation, and certainly challenges the status quo, which might ruffle the feathers of some architects and builders who are well established in the (traditional) building industry.

The forward-thinkers are celebrating, however. So are the home-owners who have used containers to build a house without ending up with hundreds of thousands of dollars of debt. The shop-owners of pop-up stores and cafes have joined the party, as have some mobile services and low-income housing developers.

Shipping containers definitely have a place in the world of architecture and construction, but their inherent flaws and limitations can’t be ignored. In time, and with more experience, building challenges will be overcome more efficiently and we’ll see the cargotecture trend expand even further.

Ready to get your project started?

At Premier Box we will match the right shipping container, new or used, to your building project. We can also complete modifications onsite at our Narangba depot. Speak to us today for the best advice and service in the industry. Call 07 3888 3011.